PRODUCT CATALOG

RELATED PRODUCTS

Lined composite steel pipe

| pipe size: | DN50-3200 |

| clad thickness: | 0.5-12mm |

| base thickness: | 3-60 mm |

| Pipe length: | 1-13m |

Product Description

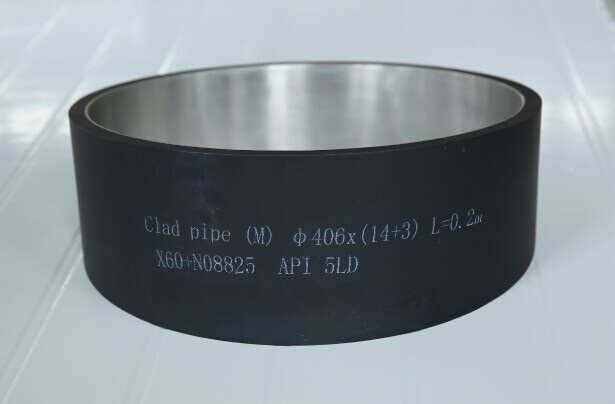

Huilin offers a variety of CRA clad or lined steel pipes including longitudinal seam clad steel pipe, helical seam clad steel pipe and seamless or welded lined steel pipe, and produces the corresponding elbows etc.cra lined steel pipe size DN50-3200,base thickness 3-60 mm, clad thickness 0.5-12mm, Pipe length 1-13m, in accordance with API Spec 5LD, DNV-OS-F101, SY/T6623 and CJ/T192. The products can be widely used in high corrosion environment, such as oilfield exploitation, oil and gas gathering and transportation, oil and gas transportation, corrosive medium transportation, petrochemical industry, pressure vessels, food industry, chemical fertilizer, pharmacy, sewage treatment, seawater desalination and drinking water etc., and are of high performance to price ratio.Longitudinal or helical seam CRA clad steel pipe:

Use hot rolling metallurgy composite plate or coil as material, modern advanced pipe-making technology (UOE, JCOE, COE and SAWH) to forming, SAWL or SAWH, and TIG etc. combined automatic welding process to complete welding. The welding quality is stable, and the product size accuracy is high. The composite plate or coil is manufactured by hot rolling technology, which can achieve metallurgical bonding of the atom between corrosion-resistant clad and the backing layer, the binding force reaches above 200MPa, the binding area rate can reach above 99.9%, and the performance is stable and reliable. The clad can meet the corrosion-resistant specific performance requirements, and the backing layer can meet the strength and rigidity condition the structure required.

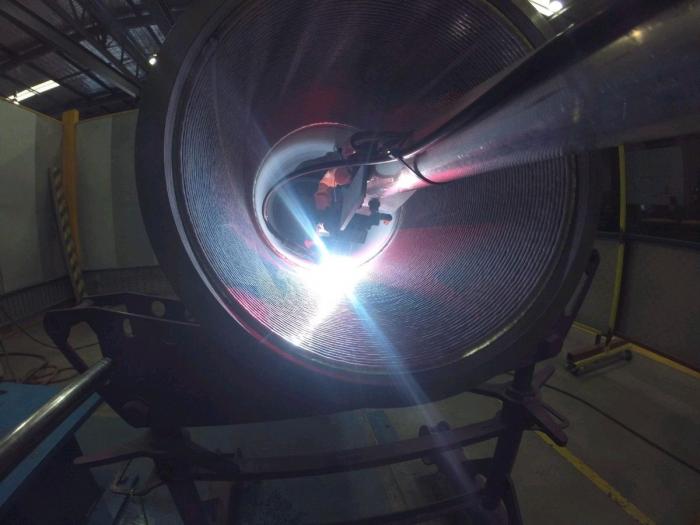

Seamless or welded Lined steel pipe:Seamless or welded carbon steel pipe as the outer backing layer, and corrosion-resistant alloy pipe as the inner corrosion layer, using the limit elasticity hydraulic composite method innovated independently by the company achieves the composite between the inner and outer pipe and forms the mechanical liner pipe. Through the composite technology, the optimal composite effect of mechanical liner can be achieved, and the shear stress between inside and outside metal layer can reach 2.0MPa (the relative standard requires 0.2-0.5MPa). Meanwhile, we develops specially the pipe ends automatic overlaying technology and NC machine tools specialized for beveling, which can process complex shape bevels such as U-bevel, and guarantees the conformity of pipe mouth diameter and bevel size, so as to operate pipe jointing on site.

PRODUCT MATERIALS BACKING MATERIALS:Q235B, Q345B, Q245R, Q345R, 16MnDR, L245~L485 (API 5L Gr.B, X42~X70), and other backing materials may be used according to user’s requirement.CRA GRADES:S30408 (TP304), S30403 (TP304L), S31608 (TP316), S31603 (TP316L), S32168 (TP321), S31803 (LC2205), S31260 (LC2506), N06625 (ASTM B443 625), N08825 (ASTM B424 825), and other corrosion-resistant cladding materials may be used according to user’s requirement.

Equipment and technology: Huilin owns advanced manufacturing process and equipment, has strong R&D team with specialists in various fields of forming, welding, mechanism, hydraumatic, electric automation and non-destructive testing. The company has two 356 and one 711 continuous forming stainless steel pipe production lines, equips with advanced welding and non-destructive testing facilities on line, and solution treatment can be carried out on line, which has high production automation and the process control is stable and reliable. In addition, the company has a number of JCOE, UOE and roll forming production lines, stainless steel welding pipe forming can be achieved utilizing single plate, and the products have large diameter and thick wall. Production lines are fitted with advanced welding and non-destructive testing equipments which have characteristics of large product size range, fast size change, and any diameter size product can be achieved within the manufacturing range.Lined composite steel pipe (mechanical forming),Lined composite steel pipe (surfacing forming)

Hits: 【Print】

Pre:TEE Next:None

xusxuan89

xusxuan89 Jack@qq.com

Jack@qq.com